NASA Tests Deployment of Roman Space Telescope’s ‘Visor’

The “visor” for NASA’s Nancy Grace Roman Space Telescope recently completed several environmental tests simulating the conditions it will experience during launch and in space. Called the Deployable Aperture Cover, this large sunshade is designed to keep unwanted light out of the telescope. This milestone marks the halfway point for the cover’s final sprint of […]

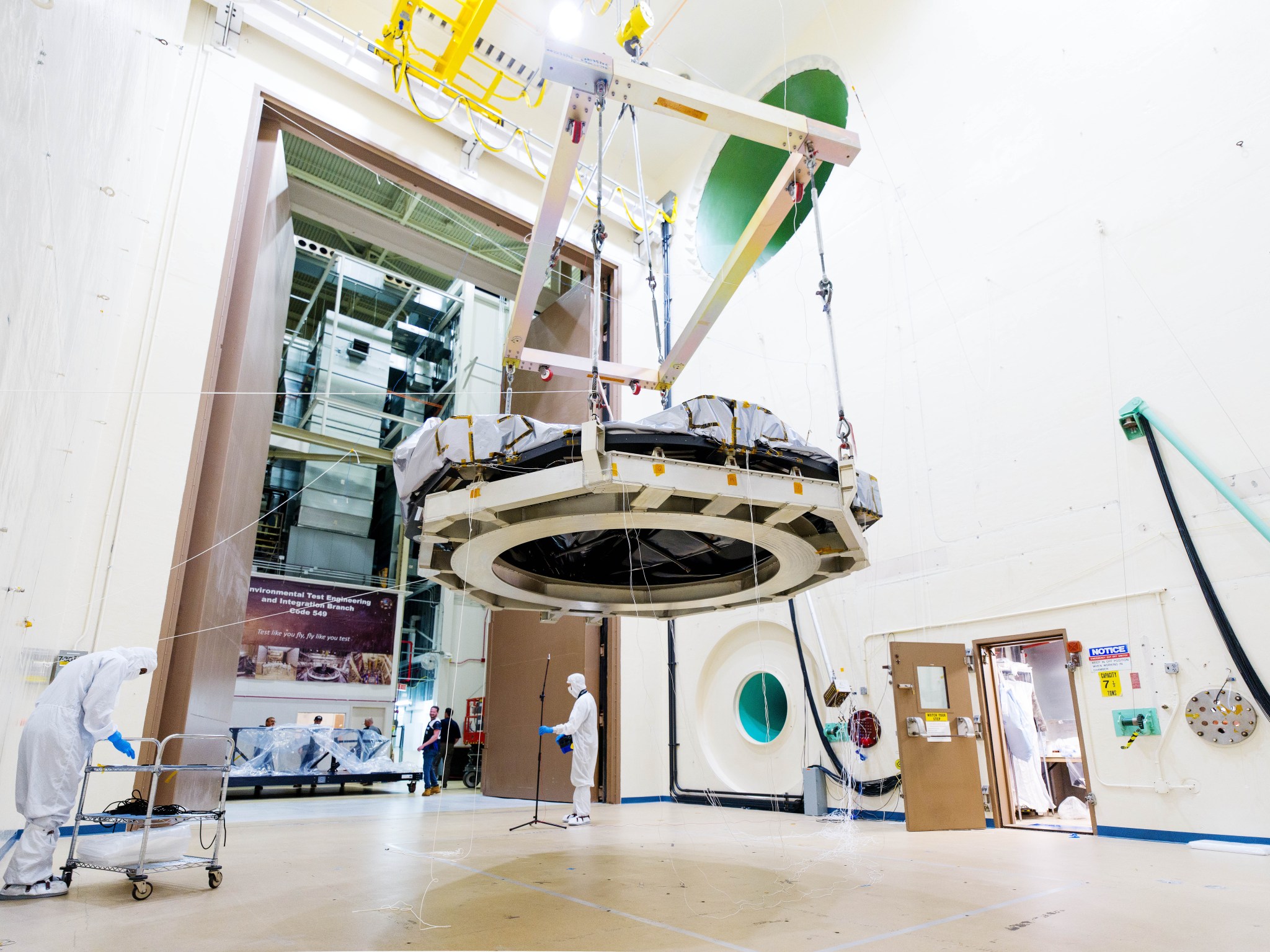

The “visor” for NASA’s Nancy Grace Roman Space Telescope recently completed several environmental tests simulating the conditions it will experience during launch and in space. Called the Deployable Aperture Cover, this large sunshade is designed to keep unwanted light out of the telescope. This milestone marks the halfway point for the cover’s final sprint of testing, bringing it one step closer to integration with Roman’s other subsystems this fall.

Designed and built at NASA’s Goddard Space Flight Center in Greenbelt, Maryland, the Deployable Aperture Cover consists of two layers of reinforced thermal blankets, distinguishing it from previous hard aperture covers, like those on NASA’s Hubble. The sunshade will remain folded during launch and deploy after Roman is in space via three booms that spring upward when triggered electronically.

“With a soft deployable like the Deployable Aperture Cover, it’s very difficult to model and precisely predict what it’s going to do — you just have to test it,” said Matthew Neuman, a Deployable Aperture Cover mechanical engineer at Goddard. “Passing this testing now really proves that this system works.”

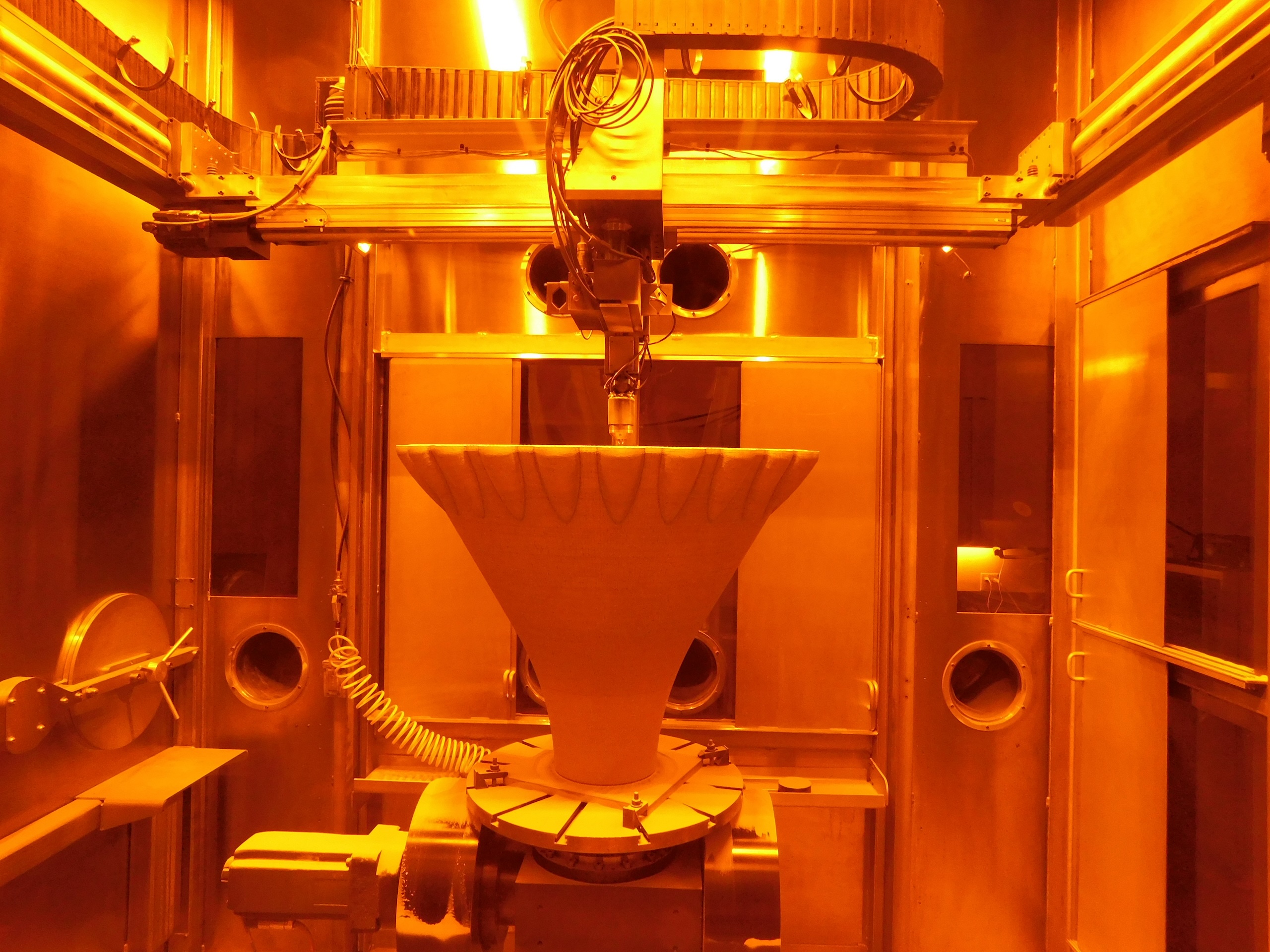

During its first major environmental test, the sunshade endured conditions simulating what it will experience in space. It was sealed inside NASA Goddard’s Space Environment Simulator — a massive chamber that can achieve extremely low pressure and a wide range of temperatures. Technicians placed the DAC near six heaters — a Sun simulator — and thermal simulators representing Roman’s Outer Barrel Assembly and Solar Array Sun Shield. Since these two components will eventually form a subsystem with the Deployable Aperture Cover, replicating their temperatures allows engineers to understand how heat will actually flow when Roman is in space.

When in space, the sunshade is expected to operate at minus 67 degrees Fahrenheit, or minus 55 degrees Celsius. However, recent testing cooled the cover to minus 94 degrees Fahrenheit, or minus 70 degrees Celsius — ensuring that it will work even in unexpectedly cold conditions. Once chilled, technicians triggered its deployment, carefully monitoring through cameras and sensors onboard. Over the span of about a minute, the sunshade successfully deployed, proving its resilience in extreme space conditions.

“This was probably the environmental test we were most nervous about,” said Brian Simpson, project design lead for the Deployable Aperture Cover at NASA Goddard. “If there’s any reason that the Deployable Aperture Cover would stall or not completely deploy, it would be because the material became frozen stiff or stuck to itself.”

If the sunshade were to stall or partially deploy, it would obscure Roman’s view, severely limiting the mission’s science capabilities.

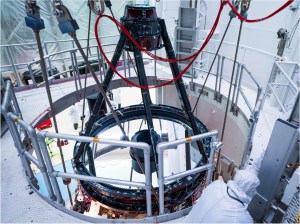

After passing thermal vacuum testing, the sunshade underwent acoustic testing to simulate the launch’s intense noises, which can cause vibrations at higher frequencies than the shaking of the launch itself. During this test, the sunshade remained stowed, hanging inside one of Goddard’s acoustic chambers — a large room outfitted with two gigantic horns and hanging microphones to monitor sound levels.

With the sunshade plastered in sensors, the acoustic test ramped up in noise level, eventually subjecting the cover to one full minute at 138 decibels — louder than a jet plane’s takeoff at close range! Technicians attentively monitored the sunshade’s response to the powerful acoustics and gathered valuable data, concluding that the test succeeded.

“For the better part of a year, we’ve been building the flight assembly,” Simpson said. “We’re finally getting to the exciting part where we get to test it. We’re confident that we’ll get through with no problem, but after each test we can’t help but breathe a collective sigh of relief!”

Next, the Deployable Aperture Cover will undergo its two final phases of testing. These assessments will measure the sunshade’s natural frequency and response to the launch’s vibrations. Then, the Deployable Aperture Cover will integrate with the Outer Barrel Assembly and Solar Array Sun Shield this fall.

For more information about the Roman Space Telescope, visit NASA’s website. To virtually tour an interactive version of the telescope, visit:

https://roman.gsfc.nasa.gov/interactive

The Nancy Grace Roman Space Telescope is managed at NASA’s Goddard Space Flight Center in Greenbelt, Maryland, with participation by NASA’s Jet Propulsion Laboratory and Caltech/IPAC in Southern California, the Space Telescope Science Institute in Baltimore, and a science team comprising scientists from various research institutions. The primary industrial partners are BAE Systems, Inc in Boulder, Colorado; L3Harris Technologies in Rochester, New York; and Teledyne Scientific & Imaging in Thousand Oaks, California.

Download high-resolution video and images from NASA’s Scientific Visualization Studio

By Laine Havens

NASA’s Goddard Space Flight Center, Greenbelt, Md.

Media contact:

Claire Andreoli

claire.andreoli@nasa.gov

NASA’s Goddard Space Flight Center, Greenbelt, Md.

301-286-1940

Share

Details

Related Terms

What's Your Reaction?

.gif)